It’s what you can’t see on MASCHINE+ that makes it different. The computer you usually have to tether can disappear, of course, but beneath that familiar outer shell it’s the many less-obvious hardware and software details that add up make the standalone experience work. Here, we’ll take an in-depth look at a few of those crucial details and tackle some of the questions you might have about MASCHINE+. What did it take to produce the first-ever standalone Native Instruments product, for example, and what might it mean for NI’s future?

To help uncover some answers I talked to the team that helped bring MASCHINE+ to the market, starting with Hardware Product Manager Chris La Pietra.

Describing what makes ‘flow’ work on a conventional musical instrument is easy, he explains. It’s not about looking at screens; it’s about muscle memory and emotion. The sort of feeling you’d get from, say, a guitar, is precisely what MASCHINE has always intended to merge with the power and flexibility of computers. With this first standalone iteration, the team aimed to squeeze that best-of-both worlds approach into one device.

The goal, says Chris, is that anyone – from live bands to DAWless studio musicians can be “completely free from the computer, and solely focused on the instrument.

“You can develop the muscle memory to play it with your eyes closed, just accessing everything with your fingertips. Combine that with Komplete’s instruments, FX, and Expansions and you have something really special.”

The company has its roots in this question of how a digital platform becomes an instrument – it’s literally the “native” in Native Instruments. NI is first and foremost a software company, and that’s apparent all over this new instrument; at its heart, MASCHINE+ is still a software-based tool. But the MASCHINE software you know runs on a computer – what had to change to allow it to make the leap to standalone hardware? In short, everything: not just the tool itself, but the entire company around that tool.

“It’s crazy, the amount of things that happen,” says Mario Altvater, the team’s UX Design Lead. “So many departments, so many people had to be committed. It meant planning on a new dimension.”

“There were many people involved,” agrees MASCHINE+ Product Owner Mariana Borssatto. “And we had to look realistically at, ‘what’s the amount of work needed to get this to the finish line?’” She speaks excitedly about the final steps the team went through to get from prototype to a finished product – the amount of attention that went into every detail the user sees from from the moment they first switch it on.

Computer Scientist Alan Kay famously said that people serious about software should make their own hardware – or at least Steve Jobs famously quoted him. But what does it take to make that hardware work? The best person to answer that is NI’s obsessive Senior Mechanical Engineer, Igor Vargotsky.

Part of Igor’s job is to take the heat off the product – literally. The heart of MASCHINE+ is an Intel processor, and the architecture that surrounds it is designed accordingly. “This specific CPU is on the low power consumption side – 14 watts,” says Igor. “So it was clear from the beginning that we do wouldn’t need elaborate active cooling – fans, pipes, etc.”

The Mk3, from which MASCHINE+ takes its shape, already featured a metal baseplate that Igor realized would be perfect for heat dissipation. The next step was simply to add material that would conduct heat from the CPU package to that baseplate. After analyzing data from various materials under thermal load, the team settled on a machined aluminum block.

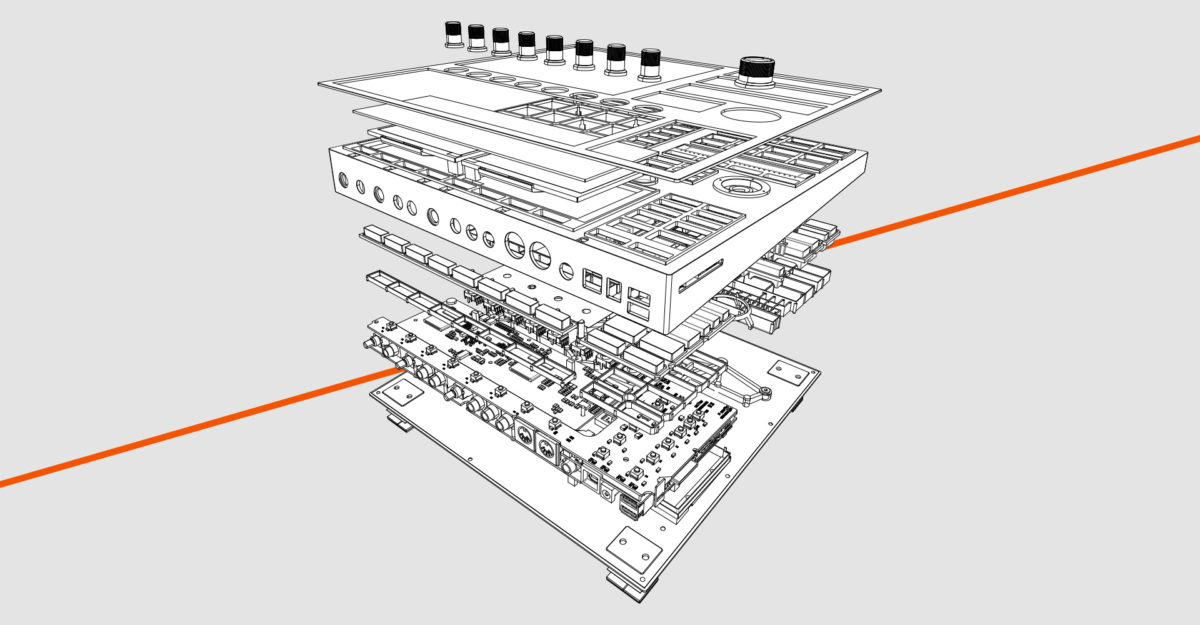

Given the shared form factor of the two instruments and the additional components that were needed for standalone functionality, it was clear that NI’s electrical and platform engineers would need to get creative in order to fit everything into MASCHINE+. The team settled on the instrument’s architectural basis fairly early on, creating the rest of the design around that. “We were able to cram everything in the housing largely thanks to the brilliant PCB layout design of the electrical engineers,” says Igor.

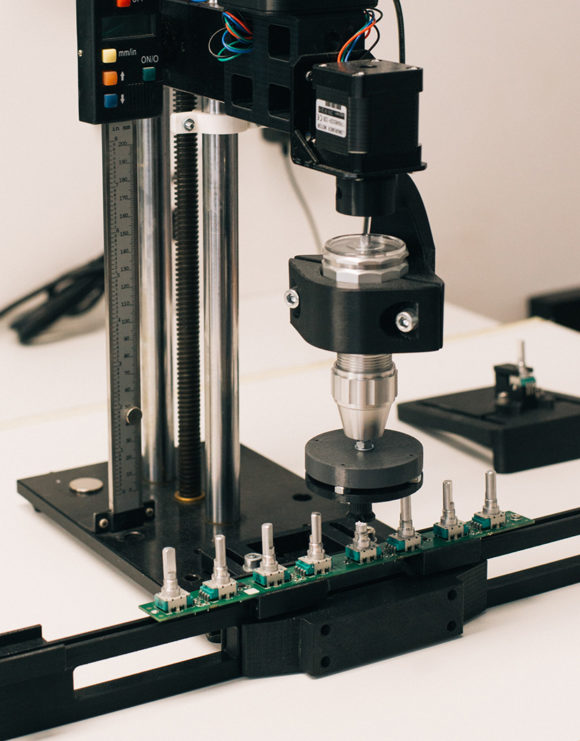

It wasn’t just a case squeezing a brain into the Mk3, though; every hardware detail required a new round of rigorous mechanical engineering and testing. “There was quite a lot of work with hardware quality assurance to enhance performance of the rotary controls,” Igor cites as just one example. “That meant a lot of back-and-forth between suppliers and user tests.”

Senior Industrial Designer Johannes Schroth reflects that even the choice to retain the Mk3 form factor itself was one that grew out of reflection. “It’s just perfectly human-sized,” he says. “It’s tried and tested. And we have all the workflows for it developed already – although there are more to come, obviously.”

“We tested the computer outside the unit a lot,” says Johannes. “But what really spoke for the quality of our design is that – when under load – the computers actually performed much better inside MASCHINE+, because of that massive heat sink.”

So does all that CPU heat translate to a hot bottom plate? Well, if you’re planning to use it to warm your lap in an unheated studio, think again. “It’s never more than ten degrees C (18 degrees F) warmer than the ambient temperature,” explains Johannes.

“It was important for us to highlight that this is not a Mk3. It’s a different beast – a more premium product,” says Johannes. “So we really focused on the details. The knurled steel knobs feel great and look amazing. The top sheet forms a really nice sandwich story with the highly functional bottom sheet. The button islands create a great visible grouping and the display works really well as an island too. I really dig the continuous frame that formed around the interface clusters. Also, the material mix that is present in the housing – metal, plastic, metal – is exactly what you’ll find on the knobs. You can see that most clearly on the 4D Encoder.

“We used a mix of modern and traditional processes for the surface finish,” he says, of the detail-work that went into the instrument’s cosmetics. “We used physical vapor deposition for the plastics and anodized the aluminum parts – which meant working through countless iterations to arrive at just the right color. We also added nice chamfers on the edges of all metal parts so you get a proper edge reflection, and added a nice spun texture on the top of the eight endless rotational potentiometers. It’s all these little details that really make the difference.”

“We have a great and experienced hardware development team that is up to any challenge,” Johannes says. “We trust in one another’s capabilities and keep learning from our colleagues as the journey continues.”

Alongside developing new hardware, bringing MASCHINE+ to life also meant refining NI’s existing software to run on the new architecture – and adapting it to their own custom, Linux-based operating system.

Vincenzo Pacella is Principal Software Engineer for MASCHINE+. He says the project presented a challenge was on two fronts: Choosing and tailoring an OS and adapting applications and instruments and effects to run in this environment for the first time. Linux was the obvious choice, he says, bolstered by toolchains that help create bespoke OS images (down to services and apps).

NI’s use of shared internal libraries made it easier to port plug-ins to the new hardware alongside the MASCHINE software itself. But the team still had their work cut out, as Vincenzo explains: “Besides porting the existing libraries, we had to design and implement a set of new libraries and microservices that interact with the main application and provide both user-facing features – connecting to WiFi networks, downloading, installing, and activating products, handling external storage devices, and so on – and internal features like error recovery, logging, and crash reporting.”

Security was also a priority from the very beginning, he says, including hardening the OS, services, and applications.

Everything about MASCHINE+’s software has been tuned in advance to run smoothly with the hardware.

The decision to use Linux came even before choosing a CPU – the team ran benchmarks on a number of different platforms before settling on the Intel Atom based on a combination of raw performance and other elements like thermal behavior and long-term availability. NI’s OS, however, is not exactly what you may think of when you imagine Linux.

“The OS is tailored to this specific hardware, and it only runs a minimal set of services that are used by the main application,” says Vincenzo. “That’s the main reason you cannot directly compare the specs of MASCHINE+ to laptops or desktop computers.”

Everything about MASCHINE+’s software has been tuned in advance to run smoothly with the hardware. Among other things, that means it requires less onboard memory than a desktop might to achieve a similar level of performance. That’s not to say the team doesn’t work hard to squeeze out even more performance, however. “There has been a huge effort to optimise the way system resources are used,” Vincenzo tells me. “Especially in terms of CPU, RAM and disk I/O – and we’ll continue along this path for the future updates.”

That ongoing tuning process is part of why you can’t run every single instrument or effect from KOMPLETE on MASCHINE+. But already, it includes dozens of instruments and effects. There’s even unofficial support for brave users with a REAKTOR license to experiment using their own ensembles on the device, for instance. That’s something you can’t do on any other standalone device (unless you build your own); it opens up unique hacks and mods for advanced users.

That means Maschine+ is something new.

“You can look at Maschine+ as a curated subset of the features that are available on modern desktop computers,” says Vincenzo. “This is never going to be a replacement for your desktop computer, especially if your workflow needs hundreds of different plugins, but rather a creative tool with a limited, curated and “healthy” selection of plugins and sounds that will keep you in the creative flow.”

Finishing MASCHINE+ has been all about bringing together all these moving parts – OS, mechanical and electrical engineering, software, voicing, what happens when you open the box and turn it on, then optimization, optimization, optimization, and more optimization. But as the whole team emphasizes, this process is only just beginning.

Even the details of how you connect to the Internet and get music required all of NI working together. And that means even if you use a different MASCHINE or KOMPLETE product, you may reap some of the benefits of the integration work that’s been done to make MASCHINE+ possible.

“You will continue to see a synergistic approach to product development, even more than in the past,” says Chris. This seems evidenced by the fact that MASCHINE and KOMPLETE KONTROL have now been brought together as a single Music Production department, led by NI’s Tim Adnitt. The main goal of this change is the sharing of technology to enable more immersive, integrated instruments in the future. And that means that whether you need pads or keys, it’s all about you as the user.

So when you do switch on that device or turn that knob, think about the fact that it’s only by the combined efforts of many people over many years that it’s possible for everything to work together. Or don’t think about that at all – and just enjoy the flow.

MASCHINE+ is out now – get all the details and order yours in our online shop. And don’t forget to check out our latest video, with hip hop producer Major Seven using his MASCHINE+ to build a beat from scratch.